The products made by the Group feature a high level of personalization and, in many cases, are prototypes with cutting-edge technological solutions. As such, they require significant efforts in terms of design, procurement, production, planning and order management.

As part of its activities, the Group acts as a systems integrator, usually acting as the prime/general contractor, managing the project for vessel construction as a whole and taking on responsibility for this. Typically, while there are differences due to the strategic business area and product type, for each order the Group directly develops project management, design, hull procurement and manufacture, while its role mainly involves integration and coordination of a qualified network of expert suppliers for the preparation of systems, accommodation and, for military vessels, weapons systems.

The need for continuous research into methods to reduce costs and development and construction times for vessel orders has led the Group to develop a business model characterized by high flexibility and integration of the main business processes as well as cutting-edge technological solutions. In terms of business model the Group has adopted a make or buy strategy for each step of development and construction of the vessel order, with the objective of keeping core skills and high value-added activities within the Group and outsourcing to qualified suppliers specialist activities that are low value-added or non-essential. Generally, the Group contracts during all stages of development and construction of the order, especially for design and production areas, also to ensure effective and efficient management of fluctuations in the order backlog and optimize saturation of the Group workforce.

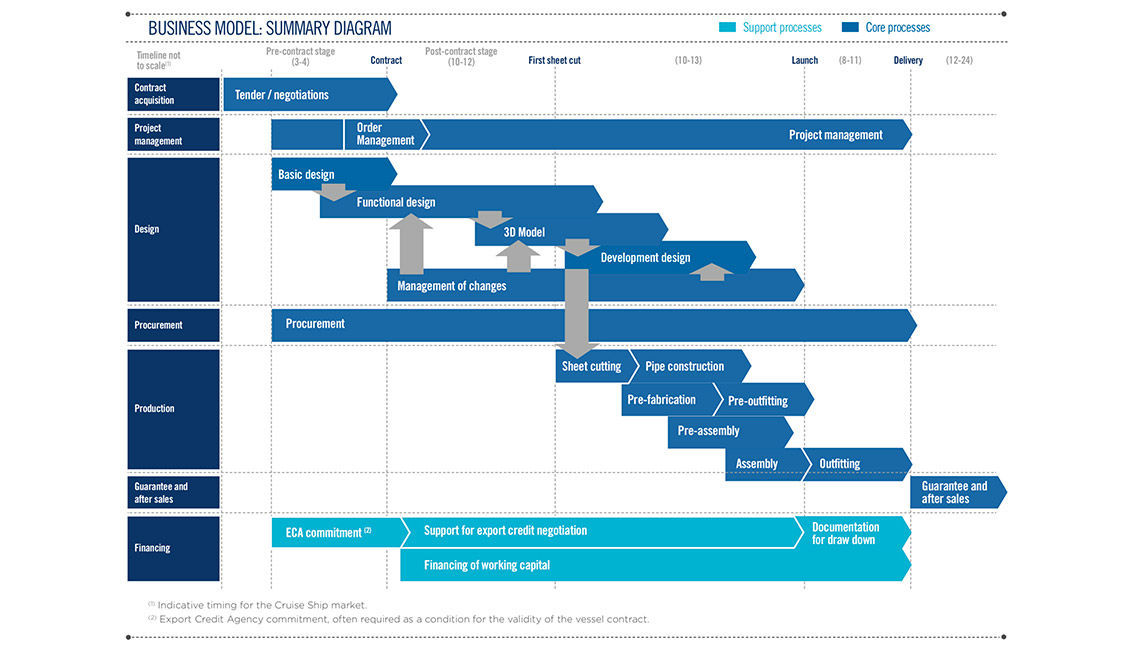

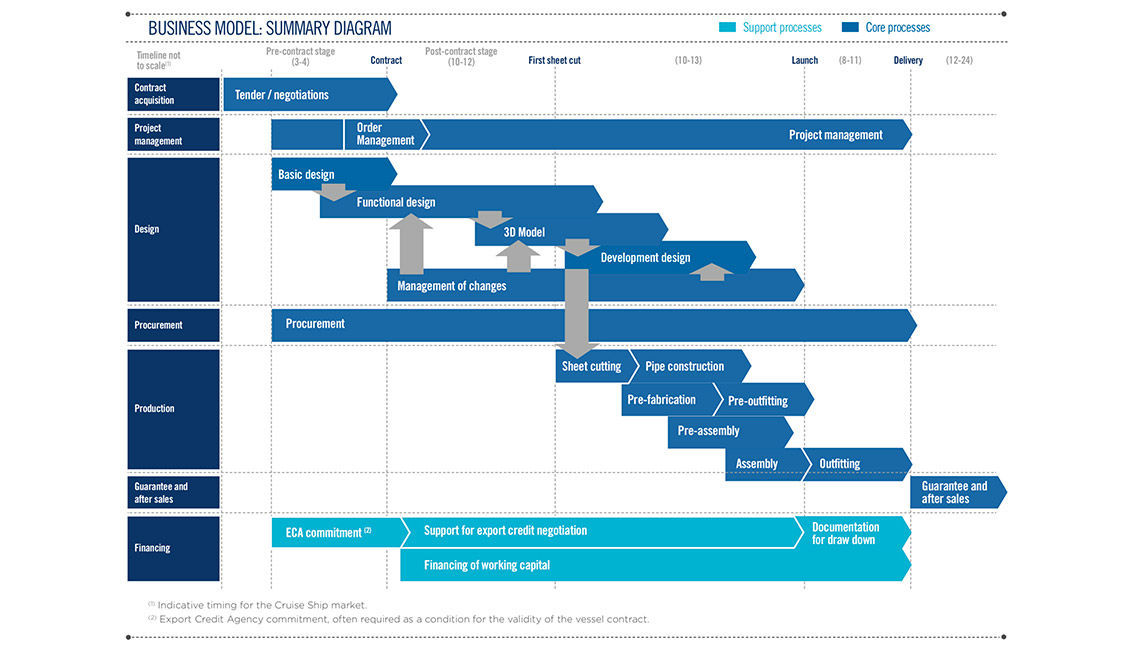

The main processes into which the Group value chain is divided, described below and illustrated in the following diagram, are: (i) contract acquisition; (ii) project management; (iii) design; (iv) procurement; (v) production; (vi) guarantee and after sales; (vii) financing.

Contract acquisition process

The acquisition of a new contract is usually the result of a tender held by a shipowner which is participated in by numerous companies, although there are some situations in which the contract can be acquired through direct negotiation where projects have significant common elements with orders previously built. Participation in the tender occurs through direct involvement of the shipowner or through market representatives. For military vessels, acquisition can occur through direct negotiations with the governing body, government agreements, or tenders held by the government authority (typically in countries without a relevant national player).

Given the highly complex nature of the product, with significant technical content and customization, the order acquisition process requires the involvement of a multi-functional work team, coordinated by an Offer Preparation Manager (OPM) who typically belongs to the marketing and sales department, and consists of representatives from the quotation department and the main functions that will be involved in the construction of the order, such as design, purchasing, production, project management, management planning and control, finance and naval contracts.

A critical success factor at this stage is the effectiveness of the inter-departmental coordination in a multi-offer context, with the departments involved in parallel also in the development of acquired orders, and with contract acquisition times that vary greatly, characterized by frequent periods of standstill and sudden accelerations. In this context, it is crucial for the profitability of the project that the activities are planned efficiently and that there is a timely assessment of the risks related to the order.

Project management process

With order acquisition, following conclusion of the contract, there is a handover between the offer preparation manager and the project manager who will manage the following stages of development and construction. The involvement of the project manager, or more generally speaking the project management department for the specific operating area, during the order acquisition phase encourages the direct assumption of responsibility by the project manager who follows the order during definition of the quotation. Acquired orders are therefore managed, within the various operating divisions, by a project management team directed by a project manager and consisting of resources with specific professional responsibilities ranging from planning and control of the order to risk management, from contract management to monitoring of project compliance and progress.

Direct management of the development and construction activities for the order is entrusted, based on area of responsibility, to the design, purchasing and production department. The latter is represented by the shipyard (or shipyards) where the order will be built.

The project manager is responsible for the outcome of the order in terms of timing, costs and quality and is the Group contact for the shipowner. Project managers, with their teams, are responsible, therefore, for the overall economic progress of a project over the entire life of the order, from signature of the contract through to delivery of the vessels and throughout the guarantee and after sales period.

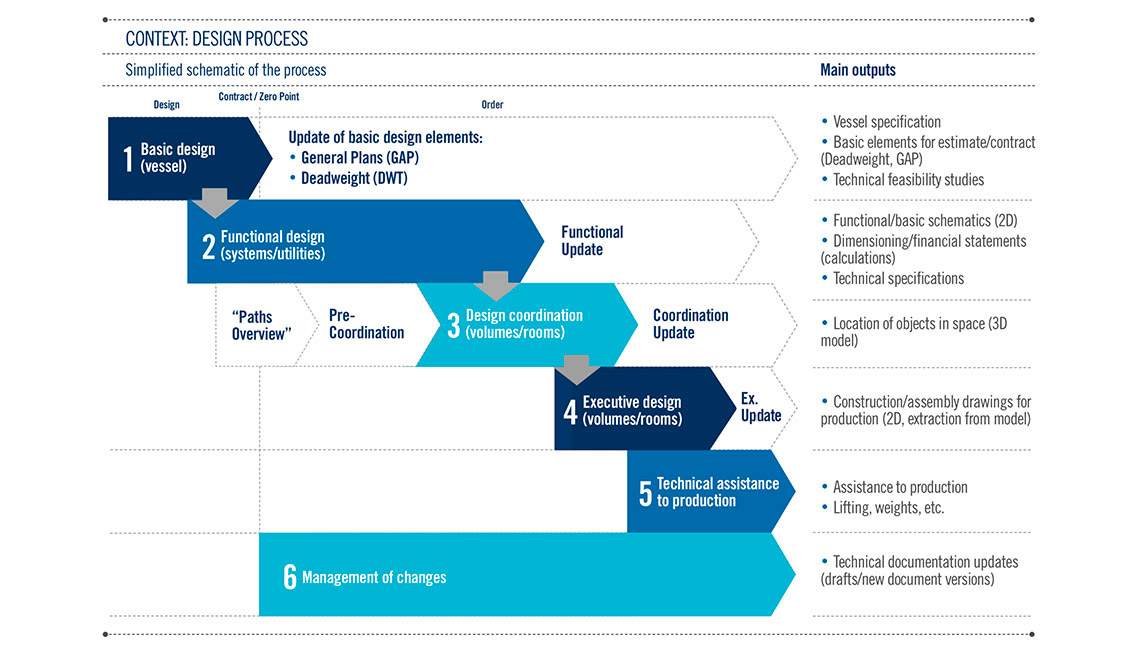

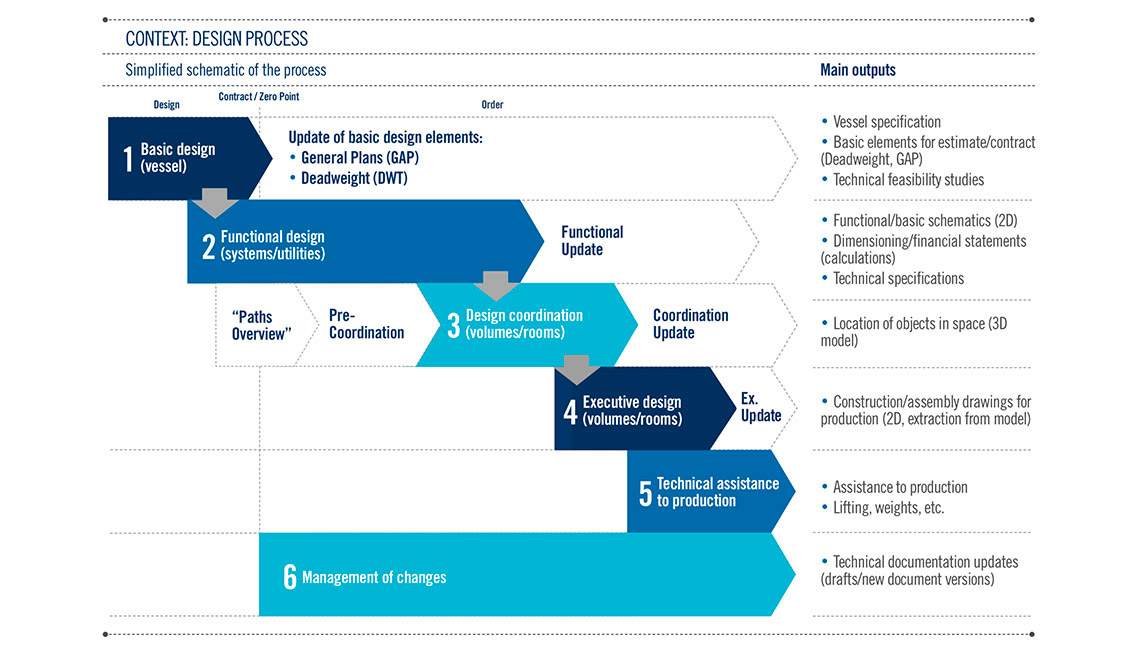

Design process

The design process is divided into a number of steps:

- basic design;

- functional design;

- development design;

- technical assistance to production;

- management of changes.

The various phases of the design process are highly integrated and interconnected, and linked with the processes of order acquisition, procurement and production. For the development of the various design phases, systematic Concurrent Engineering and Carry Over approaches are applied, with the support of a “technological database” which is the technical custodian of all design solutions and standard components for the development of projects.

Procurement process

A large part of the overall value of each order depends on the materials, parts, components and turnkey systems supplied by third parties. The Group actively manages its make-or-buy procurement strategies and therefore the size of the contribution of third party suppliers in relation to the overall value of the project.

Suppliers work in close contact with the Group for the construction of vessels, often working in the same production locations in which the vessel is being built. Given the high percentage of project value related to third party supplies, the purchasing process is critical for each vessel construction project and is therefore managed internally by units in the operating divisions or relevant units in other Group companies and the central coordination units.

Typically, operational managers oversee the purchasing processes and monitor the times - and, if necessary, adopt corrective actions - for the supply. The purchasing development function instead deals with the marketing processes of purchasing, selecting suppliers and acquiring cross-cutting services and raw materials or components common to different areas.

Production process

Sheet cutting

The "Sheet cutting" date formalizes the start of the production activities through the activities for the treatment of the ferrous materials that the hull will be made of, cutting of sheets and bar stock, bending of surfaces, etc. The machine shop responsible for this machining has a significant degree of automation and mostly internal labour, mainly dedicated to machine operation.

Pipe construction

During the initial phases of vessel construction, in parallel with construction of the hull, pipe construction is also managed, performed partly within Fincantieri and partly by expert external suppliers. Pipes made in this manner are made available for both the pre-outfitting activities, with assembly on blocks/sections on the ground, and for the later stages of outfitting in dry dock or on the dock.

Pre Fabrication

During the pre-fabrication phase, the iron materials are suitably treated, cut and shaped to the sizes and shapes required, then consolidated, based on the assembly level, in sub-assemblies and blocks. This stage features automated activities, mostly related to the manufacture of "flat blocks" (central parts of the vessel), and manual activities, mostly related to the manufacture of "curved blocks" (bow, stern and lower portions of the vessel) which require, to guarantee effective and efficient management of the variations in order backlog, systematic contracting, mostly related to the lower value-added activities, under the strict supervision of Fincantieri.

Pre Outfitting

The pre-outfitting phase is overseen by the same machine shops that later perform the outfitting phase. It involves the start of utilities systems outfitting and painting on blocks and sections, in parallel with the pre-fabrication and pre-assembly phase, and is continued on the completed vessel in dry dock in parallel with the assembly phase.

Pre Assembly

During pre-assembly the blocks are assembled into sections or loading units (units that are positioned in the dry dock). During this phase, also managed under contracts supervised by Fincantieri, the blocks/sections are preoutfitted on the ground through progressive assembly of the outfitting materials and are then painted.

Assembly

The sections manufactured during the pre-assembly phase are then made available for positioning in dry dock for the following assembly phase of the vessel using lifting equipment. The layout date is the date on which the first section of the vessel is positioned in the dry dock. The launch date is the date on which the assembled vessel leaves the dry dock (or is slid onto the staging area or transported to the apron) and floated in safety to the dock for the final completion phase. Between the layout date and the launch date, the sections are progressively assembled to make up the complete hull of the vessel.

These activities are once again performed under contract, with supervision by Fincantieri. In parallel with the welding of the various sections, the pre-outfitting of the systems and machines continues, with connection of the system lines (such as pipes, conduits, etc.) previously assembled on different sections. Also in parallel, work is carried out to complete the painting and insulation, outfitting related to the operation of the ship's platform (motor equipment ready, alignment of shafts, etc.) is carried out and payload outfitting (cabin furnishings, public areas, services, weapons systems, etc.) is started.

Outfitting

After the launch date, outfitting of the floating vessel starts in the dock; this phase includes outfitting of the minor systems and payload, i.e. the systems, equipment and fittings which serve for the vessel's use. During all the activities to execute the order, in particular in the period between the launch and vessel handover, there are formal deliveries of blocks, sections, areas, systems, etc. to the naval registers, the Flag Authority and the shipowner. These deliveries certify product acceptance at various levels. The performance checks on the ship are mostly carried out during the navigation tests, which are carried out a few months before delivery with the execution of the tests required by the Registers and the shipowner. The sea tests can only be carried out after having carried out the preparatory tests in the dock of the on-board plant/systems, the pre-tests of their operation and after having checked the safety conditions required by the Registers and the Maritime Authority. The end of the production phase is sanctioned on delivery of the vessel to the shipowner by the signature of the Ship Acceptance Report (protocol of delivery) which represents the quantitative and qualitative result of all the construction and testing phases. This formal process is preceded by the issue of specific documents/certificates by the relevant entities and authorities (RINA, Registers, etc.).

Guarantee and after sales process

Delivery of the vessel generally signals the start of a guarantee and after sales phase, basically related to the commitments made to the shipowner during contract acquisition, during which the Group guarantees the scheduling and management of the operations necessary to eliminate any problems encountered during the contract period, starting from the delivery of the vessel through a predefined period, supplying the necessary know-how and appropriate co-ordination of the suppliers.

After delivery of military vessels, there are frequently after-sales logistics service activities that fall within the set of activities related to the supply of spare parts and customer service (such as technical interventions following customer calls, planned maintenance or machine shop repairs).

Financing process

The main processes into which the Group's value chain is divided are flanked by a series of support processes that contribute to the efficient management of the order.

The ability of the Group to manage complex projects is based on an result-oriented organization, with central functions that control and support operating division activities according to their respective areas of skill (management planning and control, administration, treasury and corporate finance, information technology, human resources, legal, operations, quality, coordination of R&D initiatives, development of industrial systems, industrial methods and auditing).

These functions, located centrally within the corporate centre, play a role in the overall governance of the Group's business as well as providing shared services to the various operating divisions. These support services ensure, in some cases, key activities for winning contracts and the resulting margins, for example the concession of financing for export credit, the development of resources and acquisition of new talents, the operation and updating of information technology systems, the management of disputes with customers or suppliers, etc.

The centralization of these services in the corporate core is aimed at exploiting synergies between the various operating divisions due to greater standardization/harmonization of the processes and the tools employed, from the most simple transfer of knowledge and practice to better use of resources in the face of fluctuating workloads.