Towards the "Ship of the Future":

Fincantieri's Commitment to the Maritime Sector's Energy Transition

Fincantieri, a global leader in shipbuilding, is at the forefront of innovation in sustainability. Our commitment to creating the "ship of the future" is a fundamental strategic pillar, aiming to transform the maritime sector to be greener and more technologically advanced. Our ambition is to develop technological, safe, and efficient ships that respect the environment and improve the quality of life on board through cutting-edge digital solutions.

With the 2023-2027 Industrial Plan, the Group has outlined a clear path to achieve these goals, focusing on technologies related to alternative fuels, such as liquefied natural gas (LNG), hydrogen, fuel cells, and overall digitalization.

From Ship to "Floating Smart City": Fincantieri's Technologies for a Sustainable Future

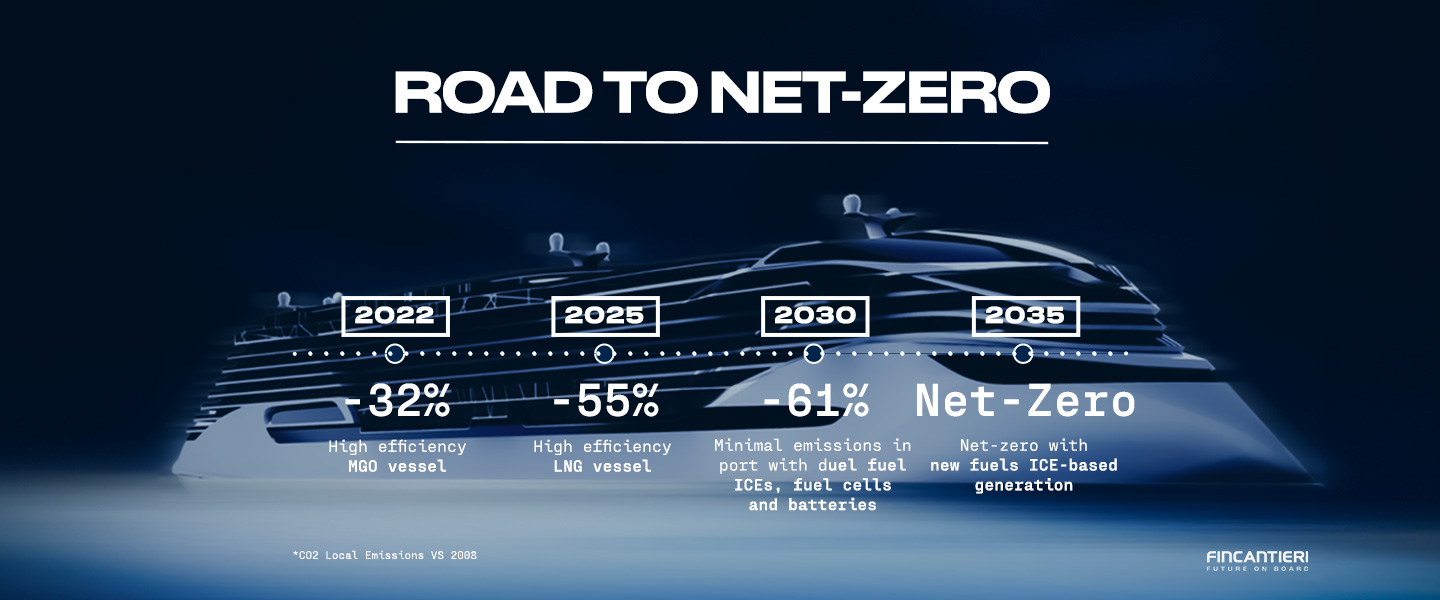

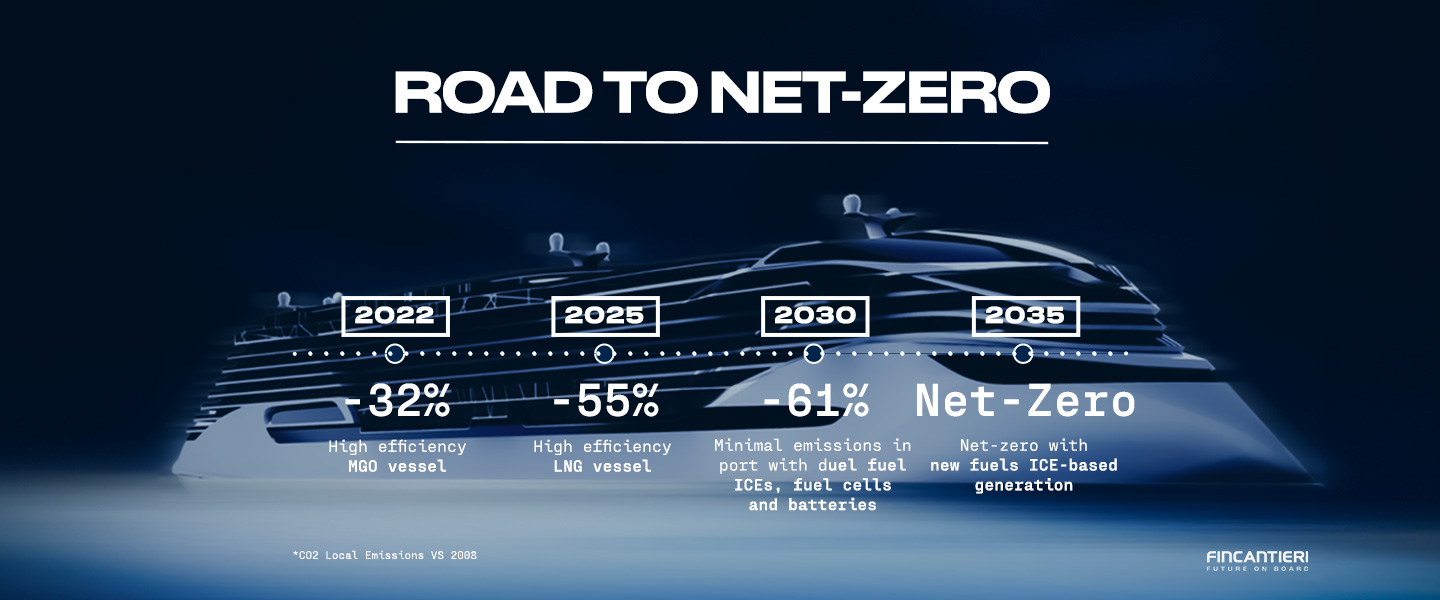

According to Fincantieri's CEO, Pierroberto Folgiero, the Industrial Plan "expresses the ambition to establish ourselves as world leaders in the realization and lifecycle management of the ship of tomorrow, which we see as a floating smart city in all respects, a platform distinguished by digital and green content." The ongoing transformations are completely reshaping the future of navigation, and as outlined in the 2023 Sustainability Report, we have set our Roadmap to Net Zero, a phased approach aiming for the complete energy transition of the entire maritime ecosystem. In this context, Fincantieri has embraced the challenge of decarbonization by introducing various green technologies, focusing on a mix of solutions to identify the most effective ones.

Ecodesign

Fincantieri's ships follow a procedure called "Eco-Sustainable Design" or "Ecodesign," characterized by the presence of the most advanced technologies in energy savings, emission reductions, high performance, and high quality of the adopted technical solutions. The ships built are highly connected, energy self-sufficient, lighter, equipped with "green" or hybrid propulsion systems, and capable of recycling up to 90% of the waste produced. For their design and construction, all international best practices aimed at minimizing the environmental impact of ships throughout their lifecycle are followed and anticipated. Thanks to the technologies widely used today, Fincantieri's ships can thermally recover up to 20% of the energy contained in the fuel. Recent efficiency improvements in the ships' non-propulsion systems have further reduced consumption. For example, on a ship of about 130,000 GRT (Gross Registered Tonnage), it is possible to reduce up to 1,200 tons of fuel per year, equivalent to about 7% of the ship's annual consumption for these systems.

Liquefied Natural Gas (LNG)

Liquefied natural gas (LNG) is one of the most effective solutions to reduce CO2 emissions in the maritime sector. Fincantieri adopted this technology for the first time with the delivery of the Sun Princess in February 2024. This ship, with a gross tonnage of about 178,000 tons and a total capacity of 4,300 people, is the largest ever built in Italy. The use of LNG allows for a reduction in CO2 emissions by up to 55% compared to traditional fuels. Fincantieri has also signed agreements with companies like TUI Cruises to build new concept cruise ships with primary LNG propulsion.

In addition, in 2022, we signed an agreement with Explora Journeys, the luxury brand of MSC Group's Cruise Division, to build two cruise ships with hydrogen-powered fuel cells and LNG engines. This memorandum of understanding also includes updating the designs for two naval units already on order, allowing the installation of a new generation system based on LNG.

Hydrogen and Fuel Cells

Hydrogen is considered a key energy carrier for decarbonization, especially for hard-to-abate sectors and heavy mobility. If produced from renewable sources, it does not emit CO2. Fincantieri launched "Wave 2 the Future," an IPCEI (Important Project of Common European Interest) project for the creation of a hybrid propulsion system, consisting of fuel cells and reciprocating engines, both powered by hydrogen, the development of a combined cycle powered by hydrogen for electricity generation, and finally, for the design, development, construction, and certification of two cruise ships with two different technologies. Through this project, we aim to create an innovative production chain for the use of hydrogen in the maritime sector, with the Group itself as the leader.

We have also realized the ZEUS (Zero Emission Ultimate Ship) project, a 25-meter-long laboratory ship entirely powered by hydrogen through fuel cells, in collaboration with the National Research Council (CNR) and the Universities of Genoa, Naples, and Palermo. ZEUS is the world's first certified and navigable experimental unit, with an autonomy of about 8 hours of zero-emission navigation at a speed of 7.5 knots.

In addition to hydrogen, we are exploring the use of ammonia as an alternative fuel. Ammonia, if used in fuel cells, can offer a zero-emission solution, although significant challenges remain in terms of storage and safety. Fincantieri is also open to the possibility of using nuclear energy for ship propulsion. This solution, still under study, could represent another alternative to achieve zero emissions by 2050, ensuring a constant and low-emission energy source.

Digitalization

Digitalization is crucial for improving operational efficiency and reducing the environmental impact of ships and shipyards. It enables optimized resource management, predictive maintenance, and energy consumption efficiency. Fincantieri is strongly committed to developing advanced digital solutions, as in the case of the IPCEI project "CLOUD 2 THE FUTURE."

Moreover, the adoption of the digital twin, a virtual replica of ships, allows continuous monitoring of operational conditions and real-time performance optimization. This innovative tool enables the simulation of operational scenarios and maintenance interventions, reducing downtime and operating costs.

In the vast sea of digitalization, there is also the development of advanced automation and control systems. Fincantieri is implementing autonomous navigation solutions and maritime traffic management systems, enhancing safety and efficiency in naval operations. Additionally, onboard connectivity is being improved through the integration of IoT (Internet of Things) networks, enabling continuous communication between different ship systems and centralized operation management.

In 2024, we signed an agreement with iGenius, an Italian scale-up specializing in Generative Artificial Intelligence, to develop AI systems. The goal is to apply these technologies in both the civilian and defense sectors, starting with the analysis of data acquired from Fincantieri's Omega 360 radar. This agreement is part of Fincantieri's plan to enhance AI use, improving the performance, safety, and efficiency of its products and processes.

Towards the "Ship of the Future": Fincantieri's Roadmap

In the 2023-2027 Industrial Plan and the 2023 Sustainability Plan, Fincantieri has outlined a roadmap for designing a zero-emission ship by 2035, ahead of the global 2050 target. In compliance with the International Maritime Organization (IMO) directives, Fincantieri commits to reducing the average CO2 intensity per ton/mile by 70% compared to 2008 and reducing total greenhouse gas emissions by 50%.

Towards 2030

By 2030, digitalization will play a crucial role: ships will be connected to a network, allowing real-time data collection and analysis to optimize operations and maintenance. European funding under the IPCEI Next Generation Cloud will facilitate the development of these technologies. Fincantieri's participation in the European Commission and Waterborne Technology Platform public-private partnership aims to present zero-emission solutions for all ships and services in the maritime sector by 2030. Additionally, emissions in port will be zeroed out.

Towards 2040

Looking ahead to 2040, digitalization will go hand in hand with "green" innovation. Technologies such as selective catalytic reduction (SCR) and automatic lubrication systems (ALS) will be automated to further reduce emissions. The propulsion systems and critical systems of ships will become fully remotely controllable. Financial transactions onboard will be secured by blockchain systems, and a common digital platform will allow ship performance monitoring by managers, shipowners, banks, and OEMs.

Towards 2050

By 2050, Fincantieri envisions the birth of the first fully autonomous navigation ships, with continuous connection systems across the entire fleet. In addition to autonomous navigation, docking, loading, and unloading operations will be fully automated.

The Vision of Pierroberto Folgiero, CEO of Fincantieri

"Even before intervening in the engine room, we have already reduced emissions by 32% compared to the reference year used for this type of analysis, thanks to solutions like a system that creates large water bubbles under the hull, reducing friction and consequently significantly lowering consumption. Then there are silicon paints, the thruster doors that improve fluid dynamics. The entire ship system must be rethought to reduce emissions.

The next step is achieved with new fuels. By 2030, we will be able to have a ship that produces 61% fewer total emissions and effectively zeroes them out in port, thanks to dual fuel solutions, fuel cells, and batteries. By 2035, Fincantieri will have designed the first zero-emission ship.

Achieving the 61% and then going even further becomes an effort of the entire supply chain, an ecosystem effort. It is no longer about marine-izing a new type of fuel, which we are doing and will do; it is about ensuring that these new fuels are available in quantity and at suitable prices at the quay. That is why we are working on marine-izing hydrogen."